©

1828 Cane Sugar and "Brown Gold" Beginning of industrial confectionery production in Dresden

At the beginning of the 19th century, Saxony’s heart was already quite literally beating for the joys of the “sweet life”. This heartbeat pulsated most strongly in Dresden, where raw cane sugar could be delivered cheaply and comparatively quickly from Hamburg via the Elbe river. The growing demand soon persuaded the manufacturers to design the packaging more efficiently and to say farewell to the inconvenient principle of packing by hand. The very first machine manufacturers who rose to the challenge and quickly focused on the field of packaging technology were Spezialmaschinen- und Wachspapierfabrik Otto Hänsel and Spezialmaschinenfabrik Max Loesch.

1881 International Packaging Technology Expertise in high-performance machines grows

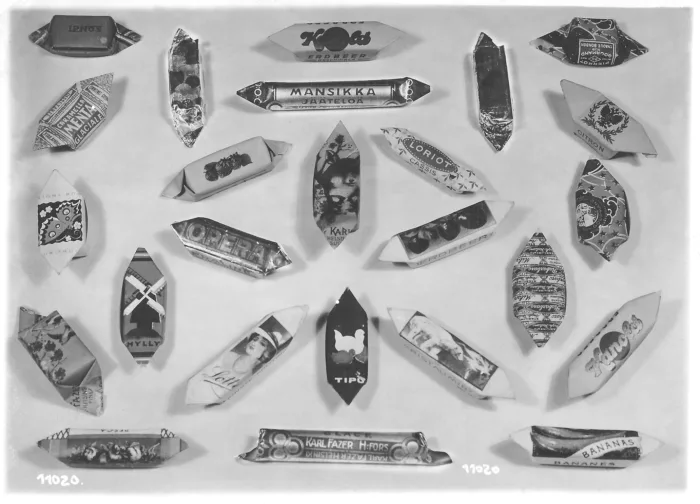

Not only in Germany or particularly in Dresden, but also especially in England, industry was working to optimise solutions and machines in the sector of packaging technology. In 1881, the Englishman William Rose had already been awarded the patent for a tobacco-packing machine, which he had developed over years of work under the most adverse conditions but with pioneering spirit, appetite for experimentation and technical talent. Encouraged by an incredibly strong demand for efficient packing machines, he founded Rose Brothers Ltd. at Gainsborough together with his brother and, with a staff of excellent engineers, concentrated very successfully on the subject of packaging technology. The following decades saw the introduction of high-performance and, for the times, highly innovative machines, for example for the packaging of chocolate, candies, biscuits and other products such as soaps and razor blades.

1934 Foundation of the Rose-Theegarten company To the forefront with entrepreneurial spirit, courage, talent and ambitious ideas

Justus Theegarten was aware of the great demand for packaging machines in Germany, which coincided with economic recovery following the great inflation. Together with his son Franz, they founded the family company in Cologne-Ehrenfeld, with six employees. Justus Theegarten maintained a close professional and personal relationship with William Rose, the founder of the English machine factory Rose Brothers, Gainsborough, and his family. From there, it was only a small step for Theegarten to manufacture and sell Rose machines under licence. This brought advantages to both sides, as the collaboration led to further development of the products resulting in the growth of Rose-Theegarten to a workforce of 50 specialists in 1939.

1939 U-boat components instead of candy wrappes The Theegarten family maintains its integrity

In the fifth year after the founding of Rose-Theegarten Verpackungsmaschinenfabrik, the war started: the manufacture of packaging machines soon came to an end. Instead, parts were produced for submarine construction. Neither Justus nor Franz Theegarten and his wife Marianne were allowed into their own factory again until the end of the war. This was probably the high price they had to pay for refusing to become members of the NSDAP. Despite his forced inactivity, Franz did not fall into idleness, but organised a temporary office in one of the children’s rooms of his house, where he started to plan his comeback. Unfortunately, a major blow came with the destruction of the factory site in October 1944.

1946 Bake and pack New strength and assurance in child nutrition

Justus Theegarten, the technical visionary and creator of a unique entrepreneurial success story, died just one year after the end of the war. His son Franz worried not only about the continued survival of the company, but also how to shield his family and children from the prevailing hunger and distress. During this period, a businessman from the Saarland, with the agreement of Franz Theegarten and the British military government, installed a baking and packing production line in the Cologne factory sheds. From that moment, Rose-Theegarten baked, grated and packed the things that brought strength back to children and not a few adults as well.

1950 Back to old strengths Development of packaging machines in Cologne

After it became possible to restart production, Franz Theegarten immediately worked on the improvement of the conditions. The construction of packaging machines was only one of the business segments of the licensors Rose Brothers, and Franz Theegarten tried at a very early stage and insistently through long discussions to convince his friend Alfred Rose that the machines should be further developed in terms of their productivity and speed. With success, as the English partners agreed that new machine types should be developed in Cologne. The results of this work soon bore fruit in terms of new revenues.

1958 First interpack The international trade fair for packaging and confectionery machinery

The Hanover Fair was already the pivot of the emerging economic miracle. Eventually there was too much competition for the coveted exhibition space, so that on account of its rapid development and expansion it became necessary to find a more adequate individual solution for the packaging sector as a whole. This was achieved with the establishment in 1958 of the newly-created Interpack, the international exhibition for packaging and confectionery machines in Düsseldorf. This signified genuine progress for the technological field of packaging and a great step with symbolic significance for the Theegarten company, as it had been no lesser person than Franz Theegarten himself, who had advocated the specialised fair in Düsseldorf towards the end of the 1950s.

1962 New headquarters in Dresden VEB Schokopack as a pioneer of industrial progress

VEB Schokopack was established in the year 1950 as a conglomerate of various traditional Dresden packaging machine building companies, but its production segment remained spatially and logistically fragmented. This led to planning and active measures in the mid-1950s to establish a completely new factory at Breitscheidstrasse 46/56 in Dresden-Reick as a central point for all those involved – the site on which the company is still located today. Four years after the beginning of the “greatest investment in the people’s enterprise for the construction of packaging machines”, the commissioning of the newly built factory, in those days one of Dresden’s most modern industry complexes, took place.

1970 Foundation of the state combine NAGEMA Machines for the food industry

The conversion of the VVB Nagema (Vereinigung Volkseigener Betriebe) to the NAGEMA state combine (NAhrungs- und GEnussmittel MAschinenbau) took place as a result of GDR state economic planning and the transformation of the old VVB structures to state combines. In the areas of foodstuffs and non-foodstuffs, the state combine factories manufactured a diverse selection of machines for the meat, beverage and also the confectionery industries. In the whole of the GDR, 14,000 employees were working in this newly created state combine group, about 3,000 of whom were employed by Verpackungsmaschinenbau Dresden. In addition to wrapping machines in a multitude of versions, they produced tubular bag machines, packaging machines for pasty goods, transport and collection plants as well as other special machines.

1971 The next generation Theegarten in upheaval

The sudden death of Franz Theegarten in 1971 caused a painful void. In this difficult phase, the young Christa Theegarten declared her willingness to take over the reins. In the first year of changed leadership, the young bank clerk and business graduate Erhard Rustler took up a position as assistant to the board. Christa Theegarten and Erhard Rustler devoted themselves in particular to the establishement of an international group of customers, as well as the development of high-performance packaging machines.

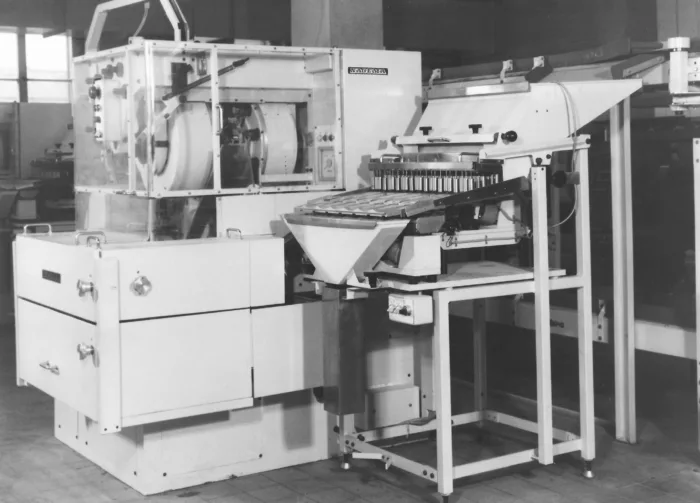

1981 A new generation of machines emerges Development of continuous motion high speed packaging machines

VEB Verpackungsmaschinenbau’s last decade was largely dominated by the EK1. Building on decades of experience, the EK1 shaped the development of a completely new generation of machines in the form of a continuously operational high-performance plant for hard caramels. VEB Verpackungsmaschinenbau presented its new model, which wrapped 1,300 pieces per minute to an amazed audience at the Leipzig Spring Fair and Interpack 1981. With only one operator a combined wrapping line, made up for example of four EK1 machines together with a storage and distribution system, could easily wrap 5,000 pieces per minute. The Dresden factory was the only supplier worldwide for such a more or less fully automatic line – a sensation for the sector!

1990 Re-focus: packaging machines Reduction of the product range to increase competitiveness

As a result of German reunification on 3rd October 1990, the Nagema state combine was converted to a public company. Almost 20 years after its formation, the era of the Nagema combine came to an end. As part of the restructuring, the packaging machine division detached itself from Nagema and was reborn as Verpackungsmaschinenbau GmbH. On leaving the state combine, managing director Gerd Schwarze had promised the workforce that he would do everything possible “to ensure the company didn’t get sold off on the cheap or even go under”. To keep going, the company had to be competitive, meaning it had to manufacture products that could be sold profitably, which would no longer be possible for almost all the items that made up the massive product range. The confectionery packaging machines however seemed to possess the necessary potential, because they already corresponded more or less to world market standards.

1991 Foundation of Pactec Dresden Goodbye to NAGEMA

Despite all the political fall-out as well as the economic and social changes, the company was still one of the world’s most innovative packaging machine manufacturers. Computeraided development, programmable control mechanisms as well as the use of the most modern electric and electronic components all became possible after reunification. This pleased not only the machine makers but also their customers, who wrapped several million tons of confectionary annually on machines from Dresden. Workforce and board together made a conscious decision to do away with the name “Nagema” in favour of a new designation that gave no indication of the company’s past.

1994 Theegarten and Pactec Strength and expertise combined as the key to success

Following German reunification, prospective buyers converged on Dresden with an eye on Pactec. Almost every day “foreign cars were to be seen in the car park indicating the interest of the international business world”, whereby the discussions with “Hänsel, Bosch, Piepenbrock, IWK, Körber, Krupp, Acma and Rowema” were only of informative character. Erhard and Christa Rustler also made their way eastwards at this time and met Pactec managing director Gerd Schwarze for initial constructive discussions. The initially very tentative and appraising interest in the former main division of the Nagema combine soon turned into specific purchase plans. And despite some critical responses in these unsettled times, the workforces and the decision-makers in both Cologne and Dresden recognised the tremendous potential that would be opened up by merging the strengths of Theegarten and Pactec.

1997 Dresden becomes the head office Consolidation of the two sites

The company management, who had expected to continue with both head office locations in Cologne and Dresden, found that the planned synergy effects didn’t materialise. So the shareholders decided on an evaluation of the facts. The result spoke for Dresden, as the Cologne site was too small to cater for an amalgamation of the two divisions. Despite the obvious advantages, the decision to move the family business away from Cologne did not come easily, especially for Christa Rustler, yet in terms of the company’s successful continuity, it was rationally correct and vitally important.

2006 Handover of responsibility Successful family business in the fourth generation

The fact that the Cologne and Dresden production programmes hardly overlapped enabled Theegarten-Pactec to offer an overall product portfolio that could meet more or less every requirement of both larger and mid-sized companies, whether in the low, mid- or high-performance range. The traditionally good relationships built up by Theegarten in the West and Pactec in the East also complemented each other perfectly and thus contributed to a successful global sales network. Markus Rustler started work at Theegarten-Pactec in 2006, and within three years his father was satisfied that he could hand over the reins after his long period of responsibility. Christa Rustler also went into well-earned retirement after an impressive 40 years at the helm. Since then, Markus Rustler has run the Dresden factory together with Dr. Röhm, who as Gerd Schwarze’s successor is responsible for the product development and production functions. This top management team is supported by 380 staff and employees.

2014 - 2017 New Factory Investing in the future

As one of the sector’s most innovative companies, Theegarten-Pactec succeeded over the years in bringing out new, flexible machines in both the intermittent and continuous segments. The products stand for innovative and future-assured engineering, excellent manufacturing quality and outstanding dependability and service life. On the occasion of the company’s 80th anniversary, Theegarten-Pactec build a new factory and office complex that fundamentally improves work organisation and enables short production routes. The investment of 30 million Euros represents a clear growth impulse for Dresden’s economic region, a clear commitment to the city on the Elbe and, not least, an important signal to our customers throughout the world, to whom we owe our success!

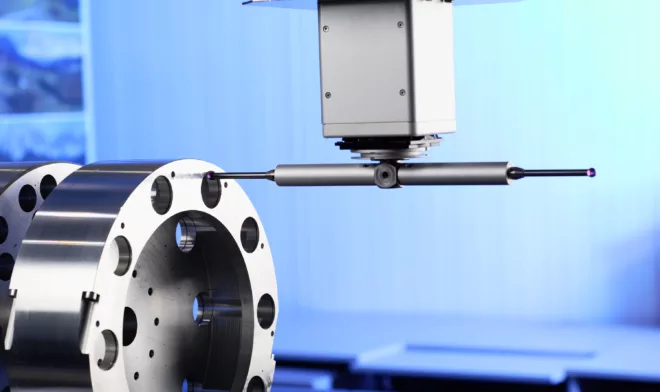

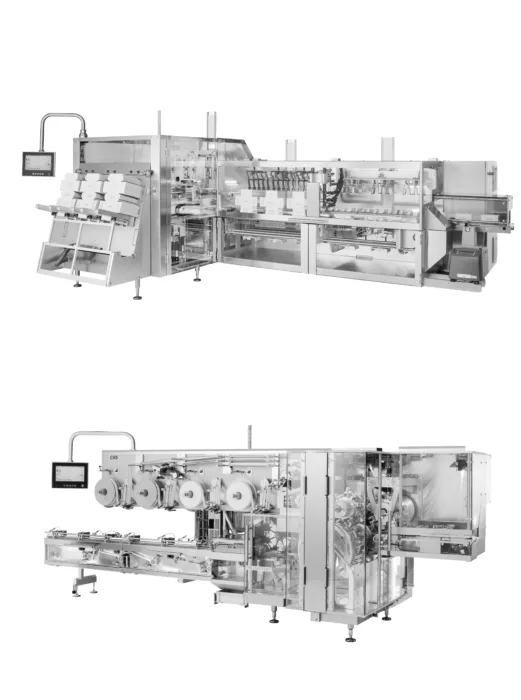

2023 Milestones in packaging technology Cartoning system BLM and flexible high-speed packaging machine CHS

The first cartoning system from Theegarten-Pactec for direct connection to high-speed primary packaging machines. Finding a suitable cartoner in this high-performance range has been almost impossible. As a result of this limitation, customers were unable to operate their primary packaging machines at full capacity. Unwanted reductions in efficiency were the result. With the cartoner developed by Theegarten-Pactec, which is perfectly adapted to connection to the high-performance machines, small products can now be processed with a high output.

CHS is the new benchmark for packaging chocolate. The modular CHS high-performance packaging machine was specially developed for the gentle packaging of chocolate products and now achieves an output of up to 1,800 instead of 1,200 products per minute. The CHS is especially flexible with regard to the possible folding types: Nine different folding types such as double twist, protected twist, top twist, side twist, foil wrap, envelope fold, bottom fold, side fold and Viennese fruit fold are possible. Additionally, the machine allows quick changes of folding type and format within only four hours.