What component do you need?

-

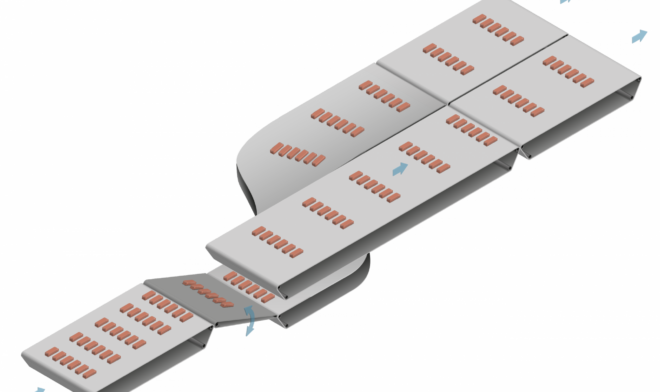

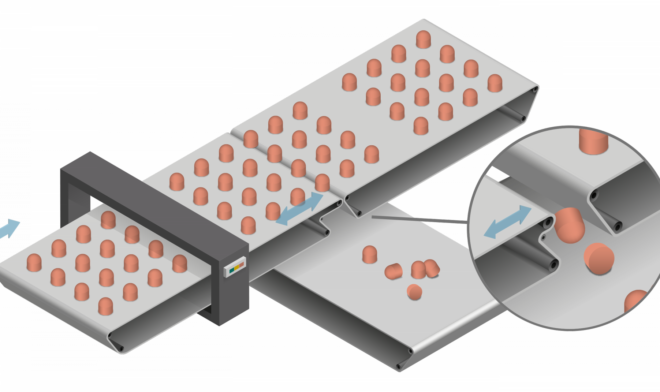

Row Doubling

Separating the incoming row structures to two levels

-

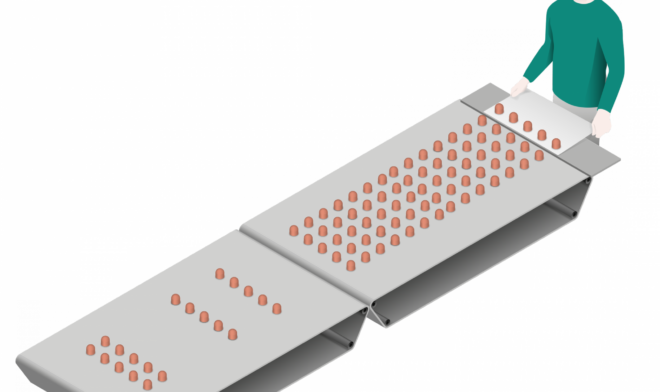

Overflow Conveyor

Storage of product overflow not transferred to the wrapping machine

-

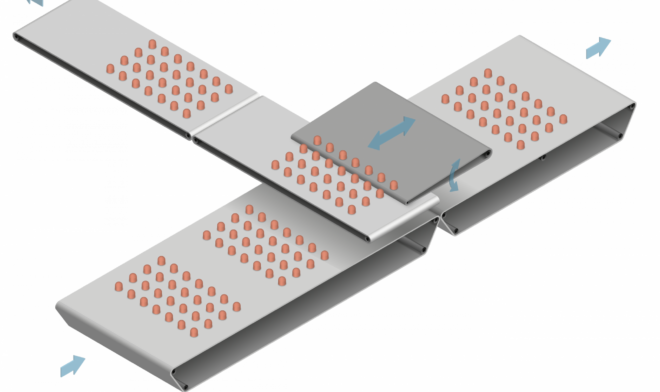

Cross Transfer Station for Products Presented in Mould Configuration

Transfer of entire product mould configuration from the main conveyor of the packaging system to the individual feeding sections of the different packaging machines.

-

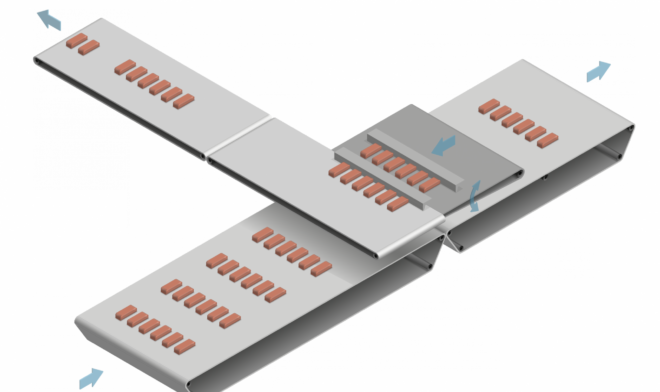

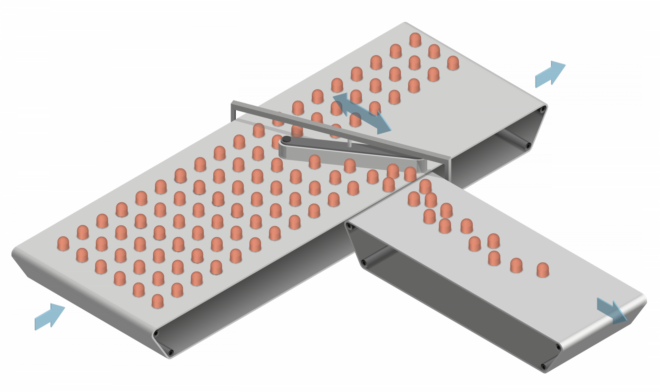

Cross Transfer Station with Pusher (Twin)

Transfer of product rows from the main conveyor of the packaging system to the individual feeding sections of the different packaging machines.

-

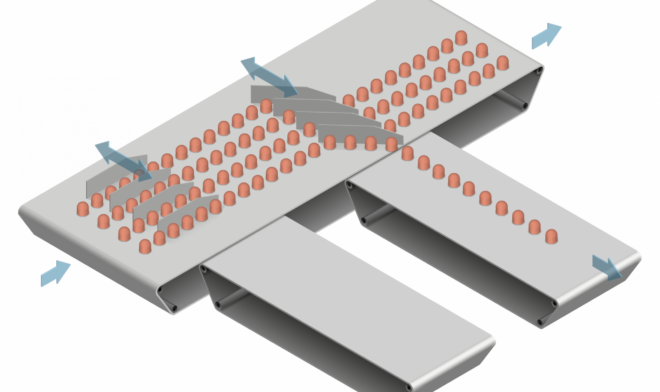

Linear Plough off Device

Moving plough off device for continuous cross transfer of product rows from the main conveyor of the packaging system to the individual feeding sections of the different packaging machines.

-

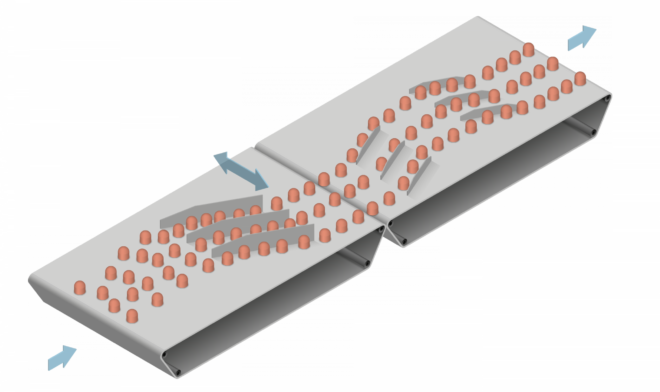

Pneumatic Product Guide

Continuous cross transfer or shifting of product rows to the individual feeding sections of the different packaging machines.

-

Row Aligner

Alignment of the products at right angles to direction of product flow

-

Lane Arrangement

Continuous arrangement of lines in direction of product flow

-

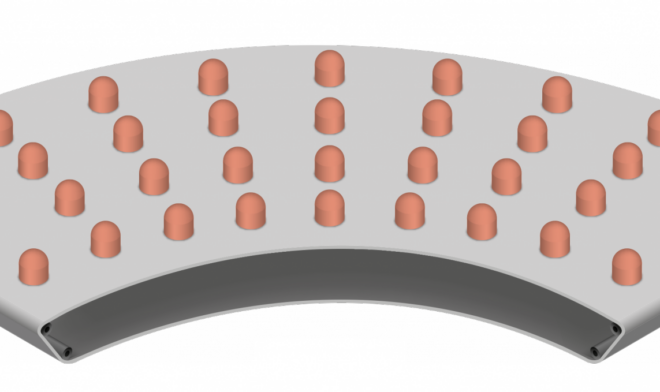

Curved Conveyor

Curved feeding up to 180° at different widths and heights

-

Metal Detector

Detection and rejection of metal contaminated product rows