A variety of bars are packaged using composite materials, e.g. a base of plastic or paper in combination with an aluminium layer. The products can therefore be easily packaged by fold wrapping and do not require any additional securing of the packaging by sealing or glue. However, packaging materials made of composite materials are not recyclable and are therefore not sustainable in view of market developments. It therefore makes sense to switch to the use of recyclable mono-materials for packaging processes. However, these materials have poor dead-fold properties, i.e. the packaging must be closed and fixed after folding by sealing or with the aid of glue so that it cannot open again.

For well-known brand products, a second packaging variant is traditionally used: a combination of two packaging materials – aluminium paper laminate and plastic packaging. This first “packaging layer”, the inner wrap of aluminium paper laminate, is required as a barrier to protect the sensitive chocolate products during the actual packaging process. When closing the outer wrap using contact sealing technology, the chocolate could otherwise be damaged by the heat that is generated or by the sealing tools used. As an alternative to this process, packaging has hitherto been glued with hot melt. The packaging specialists at Theegarten-Pactec have now developed a technology called “suction supported sealing”, which offers numerous advantages over these conventional processes.

Risks of conventional processes such as sealing or gluing with hot melt

The chocolate is packaged in a material such as plastic, by means of fold wrapping. However, since plastics have poor dead-fold properties, i.e. the packaging opens again after folding, it must be actively closed and fixed by sealing or with the use of glue.

For this purpose, during the sealing process, the sealing tool is pressed against the packaging material from the outside to connect the outer and inner flap of the plastic packaging with each other. This ensures that the packaging is fixed after folding but is still easy for the consumer to open. The problem with this procedure is that when the sealing tool is applied, the packaging material lies close to the product. In order to effectively dissipate the heat generated, the inner wrap of aluminium paper laminate is used. However, the use of two packaging materials – aluminium paper laminate plus plastic packaging – is neither environmentally friendly nor particularly cost-saving or recyclable. Therefore, the use of a sealable, and ideally even recyclable, mono-film is recommended.

The alternative, which involves the application of glue dots, ensures a permanent closure of the plastic packaging, but also has disadvantages. Clogged glue nozzles or contamination can lead to an increased susceptibility to malfunction and to the need for additional work with respect to cleaning and maintenance of the packaging machine. This reduces the efficiency of the packaging process and generates additional costs. Furthermore, the application of glue not only involves risks for the machines and aggregates, but also for the product itself. Incorrectly adjusted glue nozzles and the resulting distortion of the packaging material due to excessive glue application can result in the glue being transferred to the chocolate product and thus contaminating it.

Suction supported sealing technology – integration into the packaging process and machines

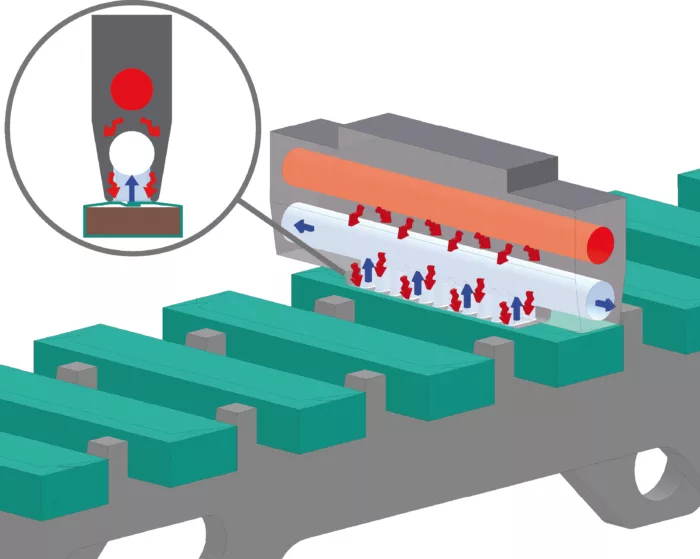

The sealing station developed by Theegarten-Pactec is located directly after the actual wrapping or packaging station. As soon as a product has reached the sealing station, the sealing tool moves to the product to be sealed at a distance of 0.5 mm to 1 mm. Negative pressure then causes the package to be sucked onto the sealing stamp. In this way, there is no direct contact between the packaging and the product during the sealing process. The heat required for the sealing process is thus distributed selectively and evenly over the entire sealing surface, thereby ensuring that there are no pressure marks or other damage to the chocolate product. Active cooling of the environment ensures additional product safety. After sealing for approx. 50 – 60 milliseconds, the contact between the packaging material and the sealing jaw is terminated when the sealing stamp moves away – which may be assisted if required by switching off the vacuum. The packaging material detaches from the sealing station and once again rests directly on the chocolate product which has now been completely packed. The sealing seam only comes into contact with the product again after it has sufficiently cooled.

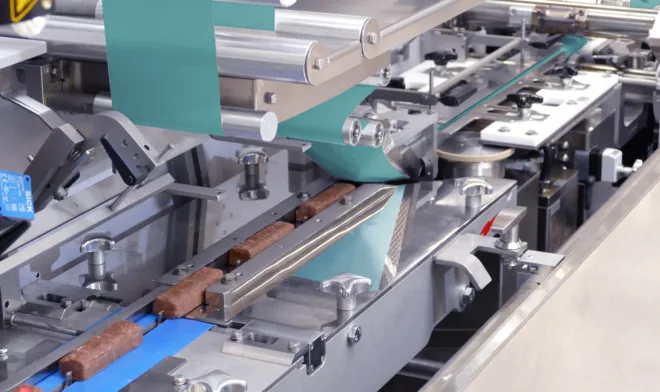

Integration into packaging machine CFW-S

The sealing station can be integrated into the CFW-S for chocolate bars in envelope fold fold with or without packaging band with up to 850 products/min. Moreover, even existing machines such as the U1-C high-performance packaging machine can be retrofitted with this new technology.

Sustainable alternative: material-saving, cost-reducing and environmentally friendly

Theegarten-Pactec’s innovative technology offers numerous advantages: Material costs can be reduced by eliminating the need for aluminium laminate to dissipate heat and protect the chocolate. At the same time, negative environmental influences caused by the production of the material are reduced. In addition, there is no need for an unwinding unit for aluminium paper or aluminium-PP composites in the packaging machine. This saves set-up and adjustment times and makes the packaging process more stable and therefore less susceptible to faults.

Thanks to the innovative suction supported sealing technology, there is also no need to apply glue dots to permanently seal the plastic packaging. Costs for glue and for cleaning and maintenance of the packaging machine can be saved. In any case, the costs for the installation of a suction supported sealing station are much lower than those for the purchase and maintenance of gluing units. Even the contamination of chocolate products with glue is a thing of the past thanks to the new technology. The new type of suction supported sealing not only ensures process safety but also additional product safety for manufacturers. The purchase of a suction supported sealing unit is therefore profitable in the long run.

Initial tests with common sealable plastic mono-films have so far produced good results. With this novel technology, Theegarten-Pactec offers manufacturers that which to score points at the POS with sustainable alternatives completely new possibilities to optimally adapt to changing consumer behaviour.