“Sustainable Packaging” is currently the buzzword in the packaging industry. Not without reason. For example, a recent representative online survey conducted by management consultants Simon, Kucher & Partners in March 2021 (“Sustainable Product Packaging”, Simon, Kucher & Partners, March 2021) revealed that for almost three quarters of the consumers surveyed, sustainable packaging is a very important issue. Paper was rated by consumers as a particularly sustainable material, 70 percent of them seeing it as an alternative to conventional materials. Not only does this increase the pressure on brand manufacturers to offer appropriate solutions, but the packaging industry also has to step up to the plate. It must respond to the wishes of consumers, retailers and, not least, to the requirements of legislators with resource-saving materials and processes and use sustainable packaging wherever possible. This is a trend that is naturally also being taken up by the manufacturers of packaging machines.

Theegarten-Pactec, the Dresden-based packaging specialist for small confectionery, has long been aware of this trend towards sustainability and has, for example, developed material-saving wrapping methods and optimised its machines for processing particularly thin films. Now Theegarten-Pactec goes one step further: the FPC5 – a modular high-performance packaging machine for bars in flow packs – has been refined so that it can now process paper-based packaging materials: on the one hand by the common cold sealing process, on the other, by the far more complex heat-sealing process.

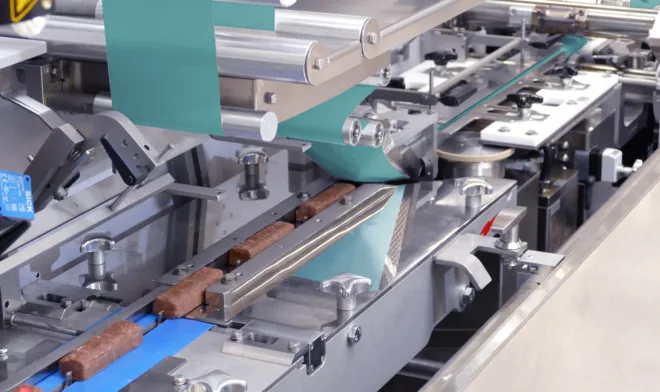

Theegarten-Pactec has developed the ideal solution for heat sealing paper-based packaging – in the high-performance range. Where speeds of 80 to 120 m/min are otherwise possible for conventional films in this range, an impressive 90 m/min is achieved for the paper-based packaging material on the FPC5. This corresponds to 600 sizeable 40g chocolate bars per minute.

Specifically, optimal processing of paper-based packaging on the FPC5 is achieved by precisely preheating the longitudinal sealing and cross-sealing areas of the paper. For this purpose, the sealing area is already preheated during the unwinding process. Thanks to a technically sophisticated pre-drawing section, the paper does not deform during this step. In this way, the paper reaches a higher initial temperature in selected places before the chocolate bars are packaged and heat-sealed. This appreciably reduces the amount of time for which heat must therefore be applied to the paper via the sealing tools during the actual sealing process to achieve the optimum sealing temperature. Thanks to this shortened sealing time, the high speed of 90 m/min can be achieved. In order to protect the sensitive packaging material, Theegarten-Pactec has also proactively adapted the sealing profile or the sealing jaws to the paper material to achieve a perfect match. Adjustable heating temperatures allow the process to be optimally adapted both to the requirements of the packaging material and the characteristics of the product to be packaged. This prevents damage to the packaging material and product and ensures that both are processed with particular sensitivity by the machine.

And the special nature of the sustainable packaging material was also taken into account in another area: Theegarten-Pactec has modified the forming shoulder for the production of paper-based form-fill-seal bags on the FPC5. Due to the material used and the geometry adapted to fit the packaging material, there is no risk of the paper creasing or even tearing during the formation of the flow pack.

Theegarten-Pactec has even taken the packaging process with the sustainable material a step further. For example, the FPC5 is equipped in such a way that so-called “gusseting”, i.e. indentation of the packaging material at the cross fin, can be easily accommodated with the paper packaging, ensuring that the paper does not tear at this point either. This allows a straight packaging end to be formed from paper. A wide cross fin, which would make it difficult to pack the chocolate bars in further, secondary packaging and would take up unnecessary space, is thus effectively avoided.

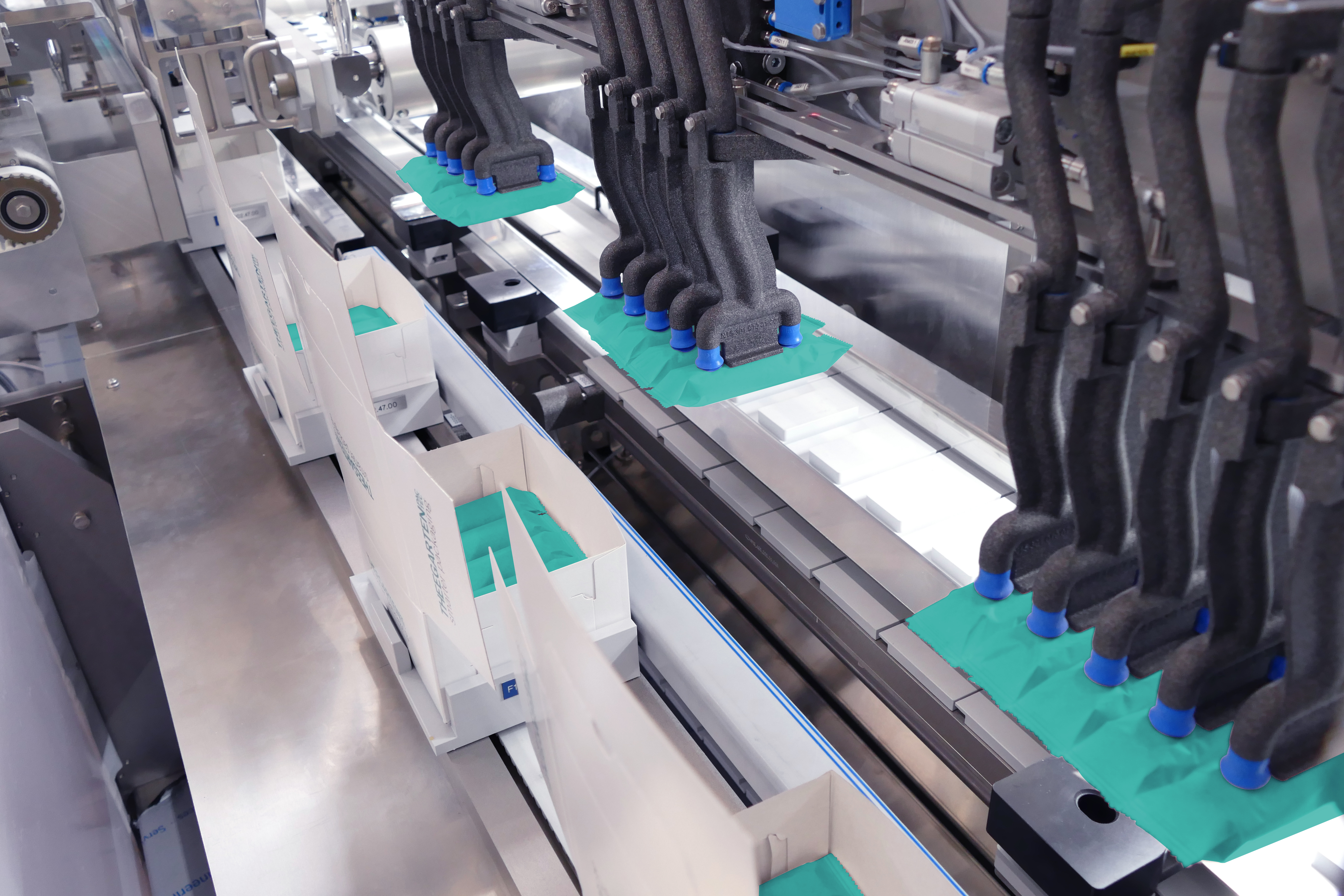

With the BLM cartoner, Theegarten-Pactec can also supply the right machine for secondary packaging in cartons. The cartoner is designed to fit perfectly with a primary packaging machine in the high-performance range. The combination of horizontal form, fill and seal machine and cartoner thus enables efficient primary and secondary packaging using paper-based packaging materials.

Thanks to Theegarten-Pactec’s patent-pending solution, manufacturers in the confectionery industry can now offer the perfect response to consumer and trade demand and score points with sustainable packaging alternatives.