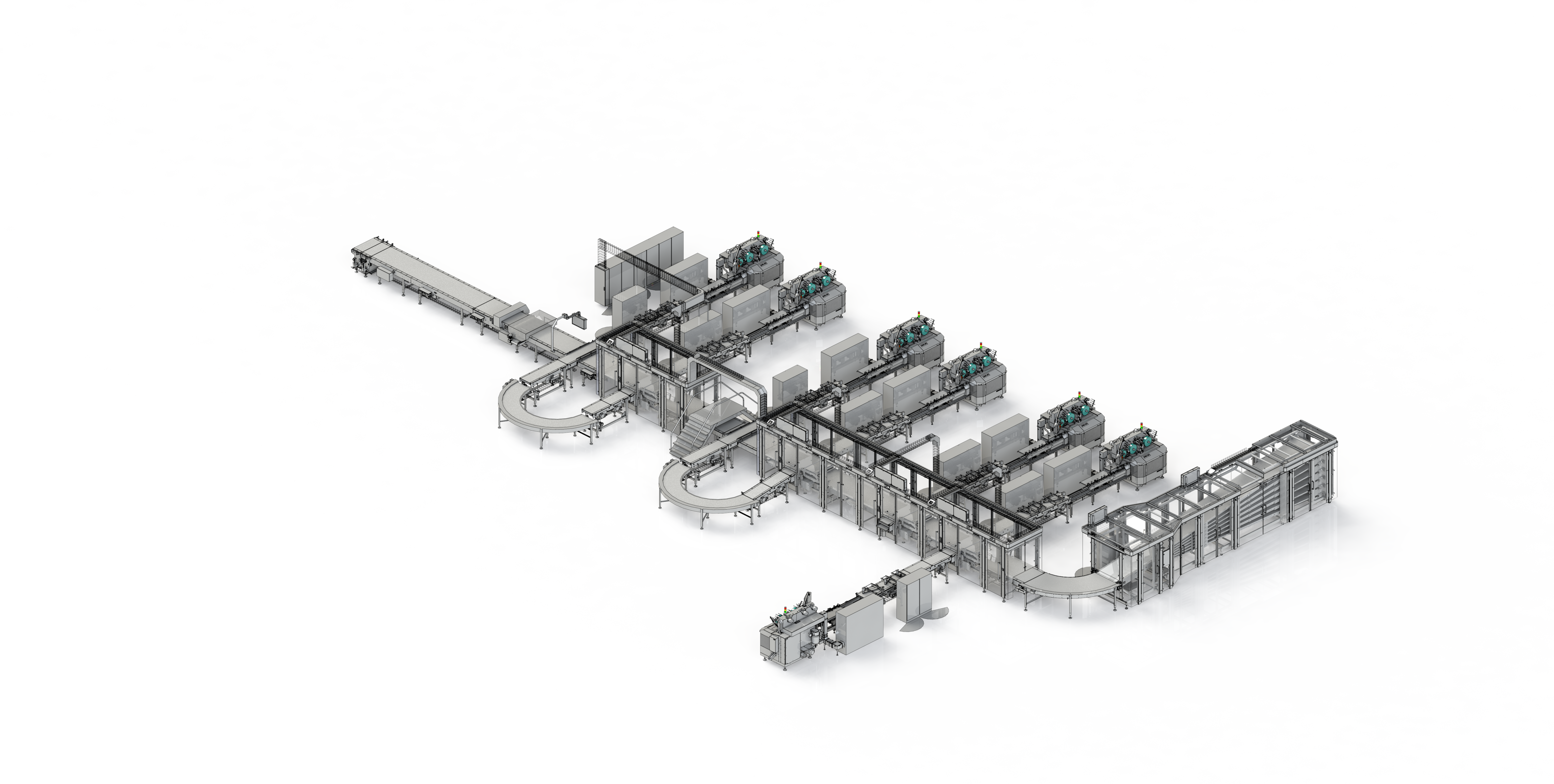

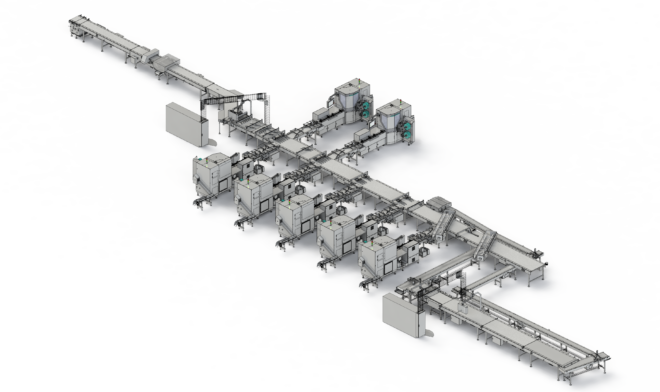

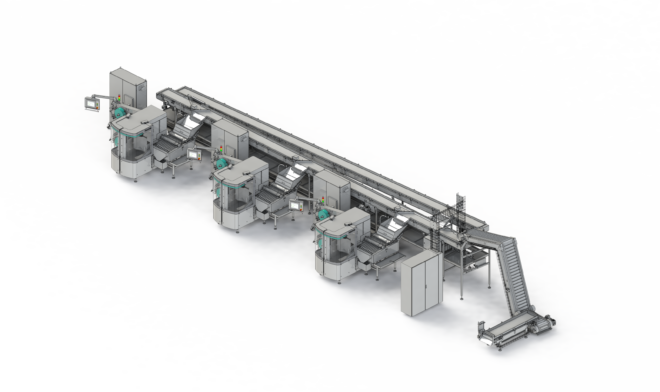

- the products can be fed to the robot system in a disordered structure

- alternatively manual feeding or direct connection to the production line

- an integrated image processing system detects the position of the products

- the robots remove the products unerringly from the product stream and place them in the continuously running feeding chain of the packaging machine

- different product formats (characters) can be flexibly and quickly fed to the packaging machine

- depending on the format, a robot places approx. 140 products/min into the feeding chain of the packaging machine

- easy access through swivelling guard doors

Vision Picker (Robot Feeding with Integrated Image Processing System)

Ein integriertes Bildverarbeitungssystem erkennt die Lage der Produkte im ungeordneten Produktstrom.

An integrated image processing system detects the position of the products in the disordered product stream.